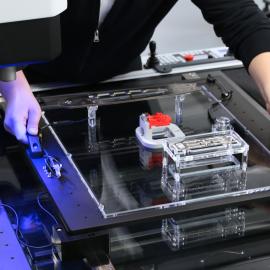

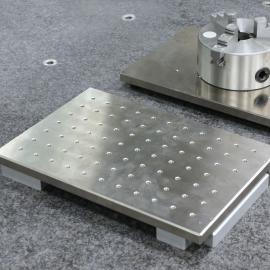

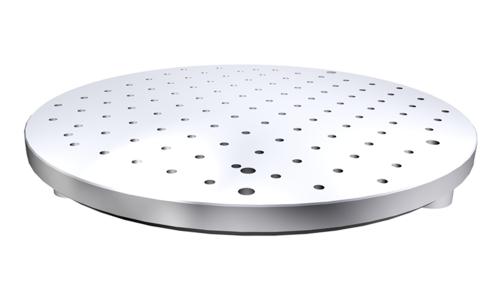

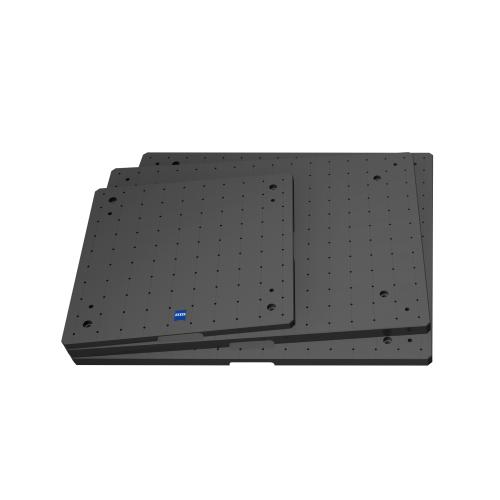

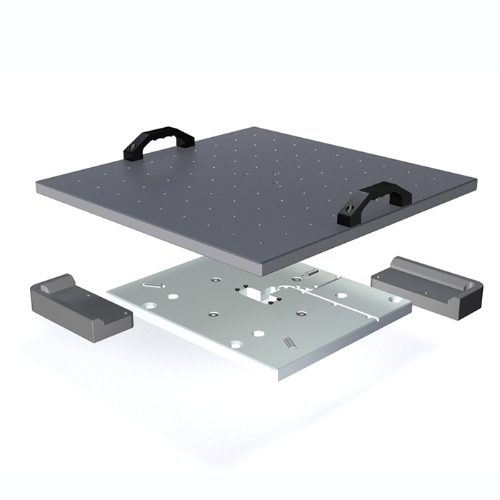

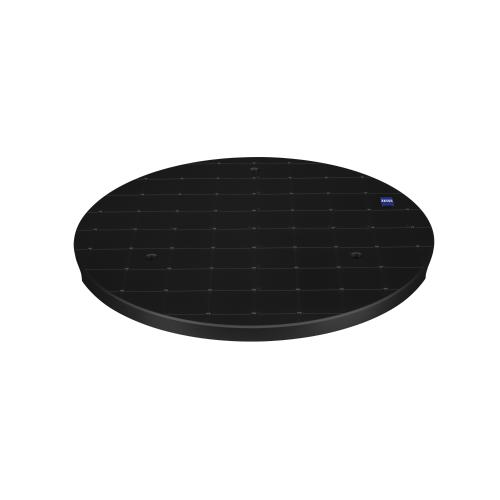

Pallets and Clamping Plates

With ZEISS pallet systems, the throughput at the measuring device can be significantly increased: While the device is measuring, the next workpiece is positioned on another pallet. The pallet can be exchanged in a matter of seconds and can be aligned for measurement without the need for re-locating the part. Grid plates are also available for securely mounting workpieces on the coordinate measuring machine. Fixtures from the ZEISS modular system are used for this purpose.

350,10 €excl. VAT

Available

784,10 €excl. VAT

Made to Order

1.281,00 €excl. VAT

Longer delivery time

1.571,00 €excl. VAT

Made to Order

7.800,00 €excl. VAT

Longer delivery time

1.466,00 €excl. VAT

Made to Order

2.121,00 €excl. VAT

Available

1.785,00 €excl. VAT

Available

155,10 €excl. VAT

Available

18.181,00 €excl. VAT

Longer delivery time

950,10 €excl. VAT

Longer delivery time

296,30 €excl. VAT

Longer delivery time

1.991,00 €excl. VAT

Made to Order

3.250,00 €excl. VAT

Longer delivery time

2.121,00 €excl. VAT

Made to Order

14.841,00 €excl. VAT

Longer delivery time

13.801,00 €excl. VAT

Longer delivery time

333,50 €excl. VAT

Longer delivery time

1.785,00 €excl. VAT

Made to Order

20.320,00 €excl. VAT

Longer delivery time

25.610,00 €excl. VAT

Longer delivery time

1.198,00 €excl. VAT

Made to Order

14.801,00 €excl. VAT

Longer delivery time

750,10 €excl. VAT

Longer delivery time

113 Items