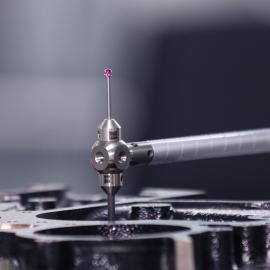

CMM Extensions

During the tactile measurement of a workpiece, many features may be difficult to access. For these cases a stylus extension can be used. While metal extensions are acceptable for touch trigger sensors, carbon fiber is a better choice for tactile scanning sensors.