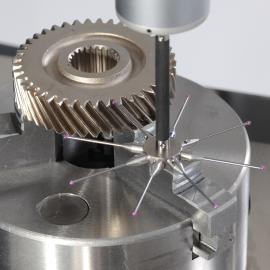

CMM Styli

The stylus is the contact point of the machine with the component to be measured. It deflects the measurement data acquisition in the probe. The size and design of the stylus used is determined by the characteristic to be measured. Key parameters for styli are accuracy, rigidity and service life, which are primarily determined by the materials used and the manufacturing technology.The quality of the stylus is a decisive factor in the quality of the measuring result. The stylus service life is primarily determined by the type of shaft processing and the quality of the connection between the stylus tip and the shaft. High-end production processes and technologies make ZEISS the technology leader in the industry.

ZEISS styli are available in various versions. A large portfolio of standard styli for M2, M3, M3XXT or M5 threads is available. Different stylus tips made of different materials and different shaft designs can be purchased for these styli. Furthermore, there are also non-threaded styli and special styli for form, contour and surface measurements.